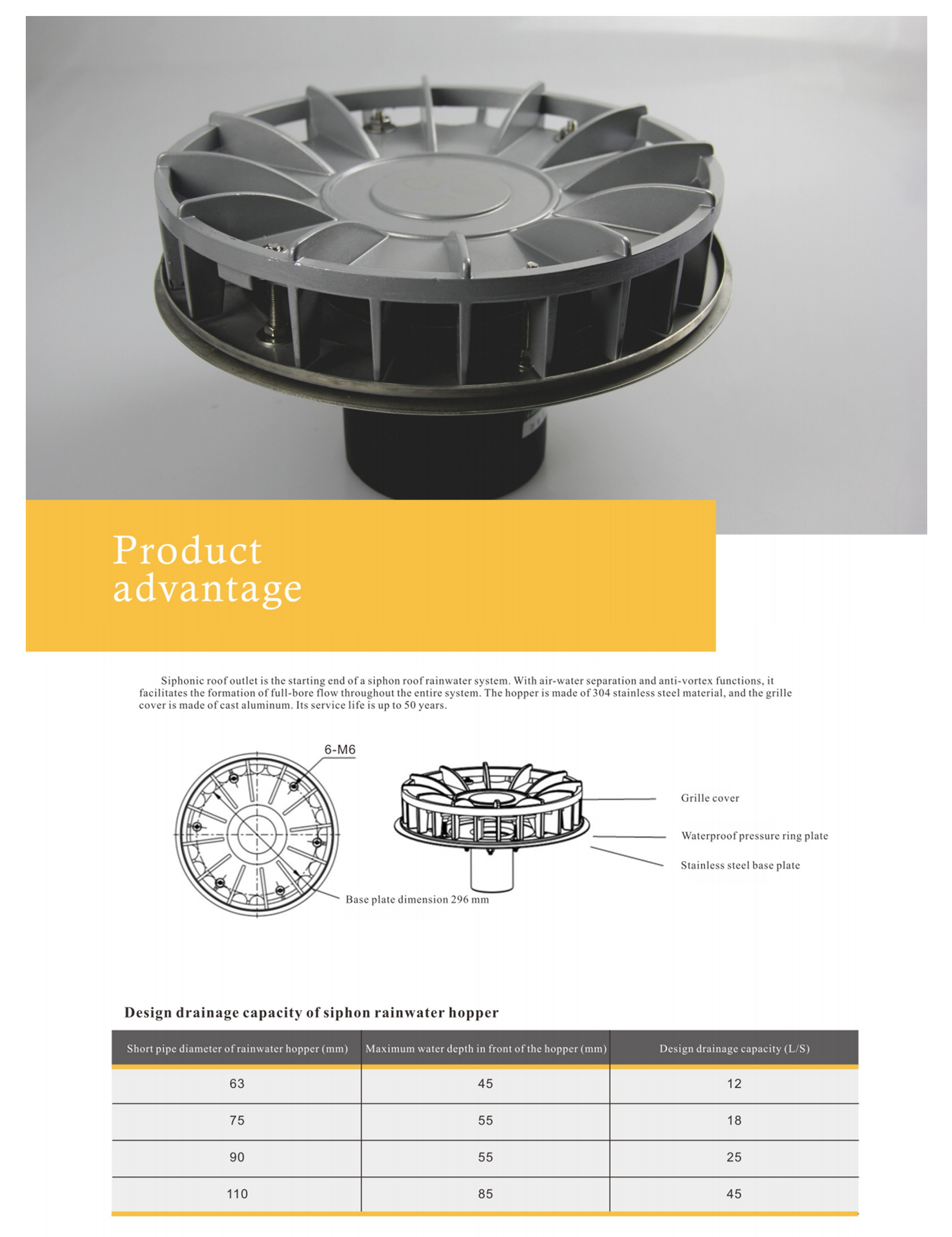

The HDPE Siphon Drainage System is a sealed pressure-flow roof rainwater drainage system composed of HDPE pipes, fittings, and specialized rainwater outlets connected via thermal fusion. Its core component is the siphon rainwater outlet, which effectively prevents air entry when rainfall reaches a certain intensity, enabling the entire pipeline system to rapidly establish a siphon effect.

| General Pipe Performance | |

| Material | High-Density Polyethylene (HDPE) |

| Common Pipe Diameter Range | DN20mm – DN1600mm |

| Common Lengths | e.g., 2.9m, 5.8m, 11.8m, or customizable |

| Pressure Rating | Common pressure-bearing range: 0.6MPa – 2.6MPa |

| Temperature Adaptation Range | |

| Fluid Temperature | 0℃ to 65℃ (short-term up to 95℃) |

| Ambient Temperature | -40℃ ~ 65℃ |

Ensuring the system’s airtightness is paramount for HDPE siphon systems, primarily achieved through the following two connection methods, with thermal fusion being the key to eliminating leaks: