The PPR (Polypropylene Random Copolymer) piping system is a plastic piping system manufactured using third-generation polypropylene raw materials through advanced copolymerization technology. It has completely revolutionized the numerous drawbacks of traditional metal pipes, establishing itself as the core choice for modern building water supply, drainage, and heating systems.

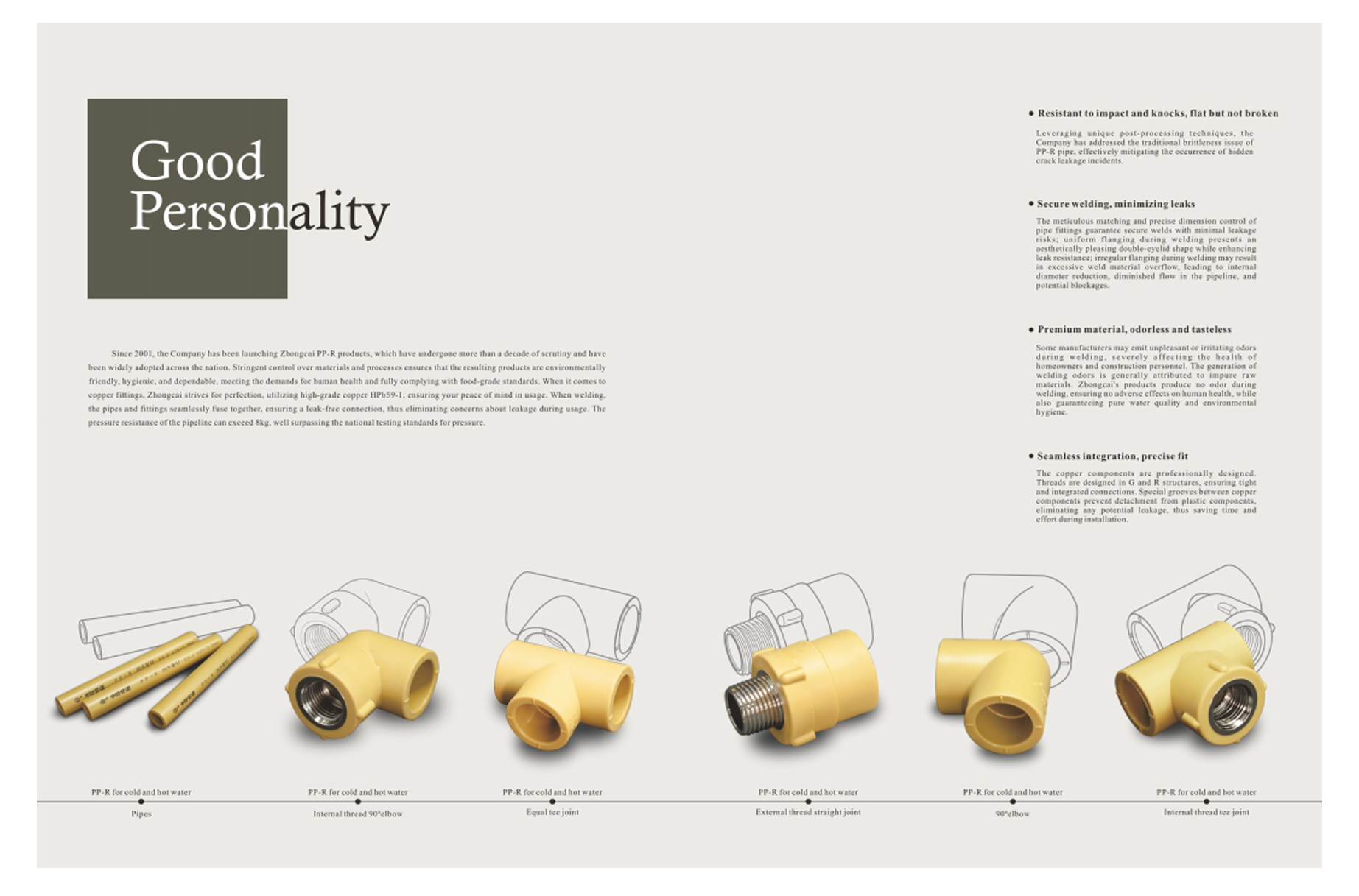

Our PPR piping system goes beyond merely supplying individual pipes; it constitutes a complete system encompassing pipes, fittings, valves, and compatible intelligent control products. We are committed to using 100% imported high-end raw materials (such as premium-grade materials from Borealis) and incorporating innovative product designs (like the three-layer composite golden structure). This ensures that every drop of water, from the source to the tap, is safe and clean. Upholding the philosophy of “Health, Intelligence, and Longevity,” the system provides a one-stop fluid conveyance solution for residential, commercial, and industrial projects.

Key Performance Indicators | Working Conditions / Performance Specifications |

Long-term service temperature | ≤70°C with a designed service life of 50 years |

Maximum instantaneous temperature | ≤95°C |

Long-term hydrostatic strength | (at 70°C, under specified pressure): 50-year service life |

Thermal conductivity coefficient | Approximately 0.24 W/(m·K), only 1/200 that of steel pipes |

Hygienic performance | All products are manufactured from food-grade raw materials, ensuring safe transport of drinking water |

Short-term hydraulic pressure test | (at 20°C)Withstand a circumferential stress of 16 MPa. |

Long-term hydraulic pressure test | (at 95°C): Withstand circumferential stresses of 4.3 MPa, 3.8 MPa, and 3.5 MPa under respective conditions |

Oxidation induction time | ≥20 minutes, demonstrating excellent thermal aging resistance |