HDPE Double-Wall Corrugated Pipe

HDPE Double-Wall Corrugated Pipe

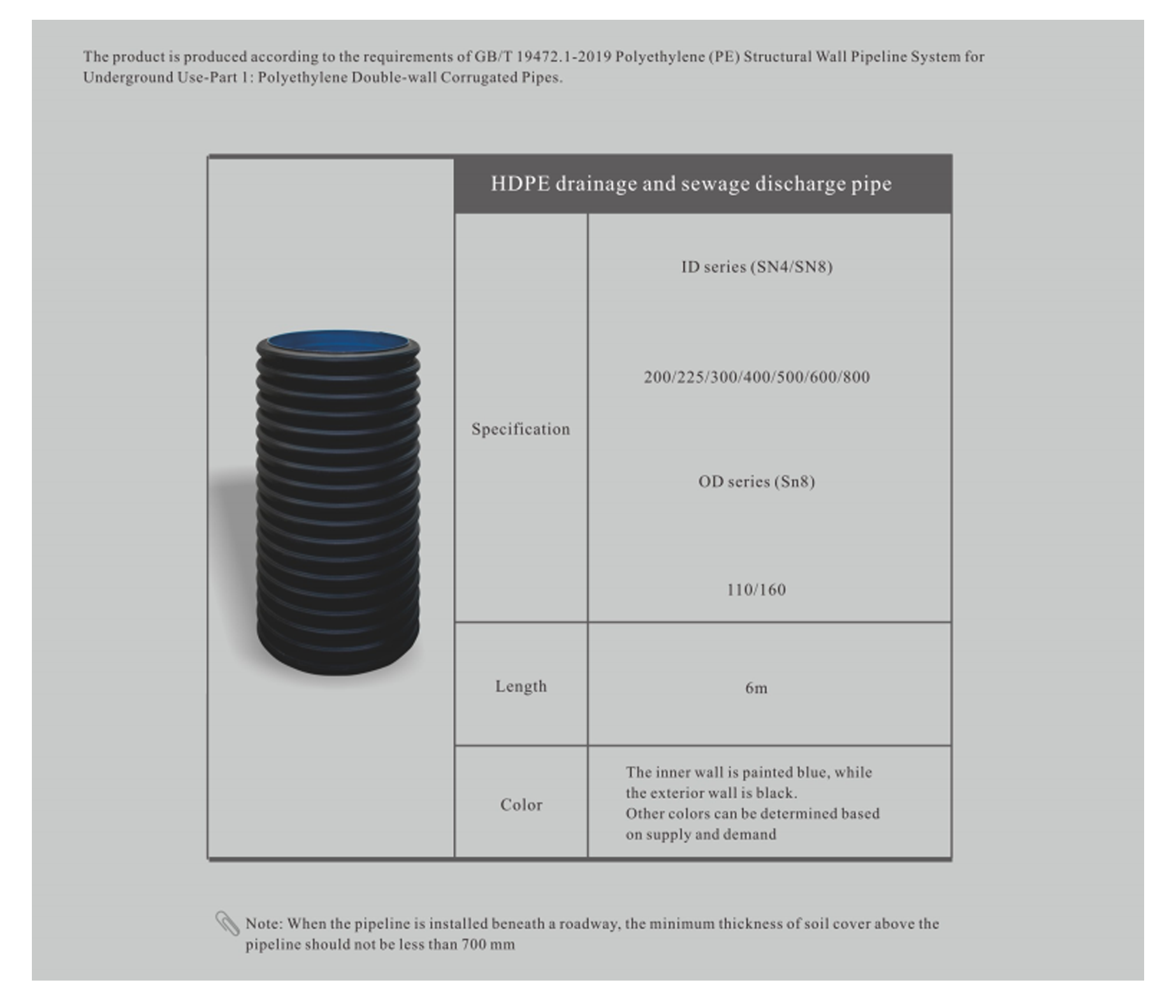

Implementation Standard: Follow GB/T 19472.1-2019 “Polyethylene (PE) structural wall piping systems for buried use – Part 1: Polyethylene double wall corrugated pipes”. In addition, there are specialized standards such as T/CECS 10022-2021 for buried drainage and sewage projects

Material: High density polyethylene (HDPE) resin, with necessary additives added.

Caliber range: Covering various specifications from DN110mm to DN1200mm.

Use: Municipal engineering; architectural engineering; Industrial applications; Roads and Mining; Agriculture, forestry and water conservancy; Cable protection.

Features: Strong ability to withstand pressure; Good economic viability; Convenient construction; Excellent hydraulic performance; Chemical corrosion resistance; Flexible and impact resistant; Durable and wear-resistant; Environmental protection and safety.

Custom orders are supported.

Description

1.Product Introduction

The HDPE double-wall corrugated pipe is a new type of pipe primarily made from high-density polyethylene (HDPE) and manufactured through a unique extrusion molding process. It features an outer wall with an annular corrugated structure and a smooth inner wall. This double-wall hollow design optimally balances rigidity and flexibility.

This pipe was first developed in Germany in the 1980s. In China, after more than a decade of advancement and refinement, its production technology has become highly mature, incorporating advanced processes such as fully digitalized control and dual-machine co-extrusion. As a flexible pipeline, it offers excellent chemical stability and an exceptionally long service life. It has become an ideal choice for drainage and sewage systems in municipal, construction, and industrial applications, and is currently in a phase of ongoing promotion and widespread adoption.

Parameter Item | Technical Specifications and Description |

Product Standard | Complies with GB/T 19472.1-2019 “Polyethylene (PE) Structured Wall Piping Systems for Buried Drainage and Sewerage – Part 1: Polyethylene Double Wall Corrugated Pipes”. Also adheres to specialized standards for buried drainage and sewage engineering such as T/CECS 10022-2021. |

Diameter Range | Covers multiple specifications from DN110mm to DN1200mm. |

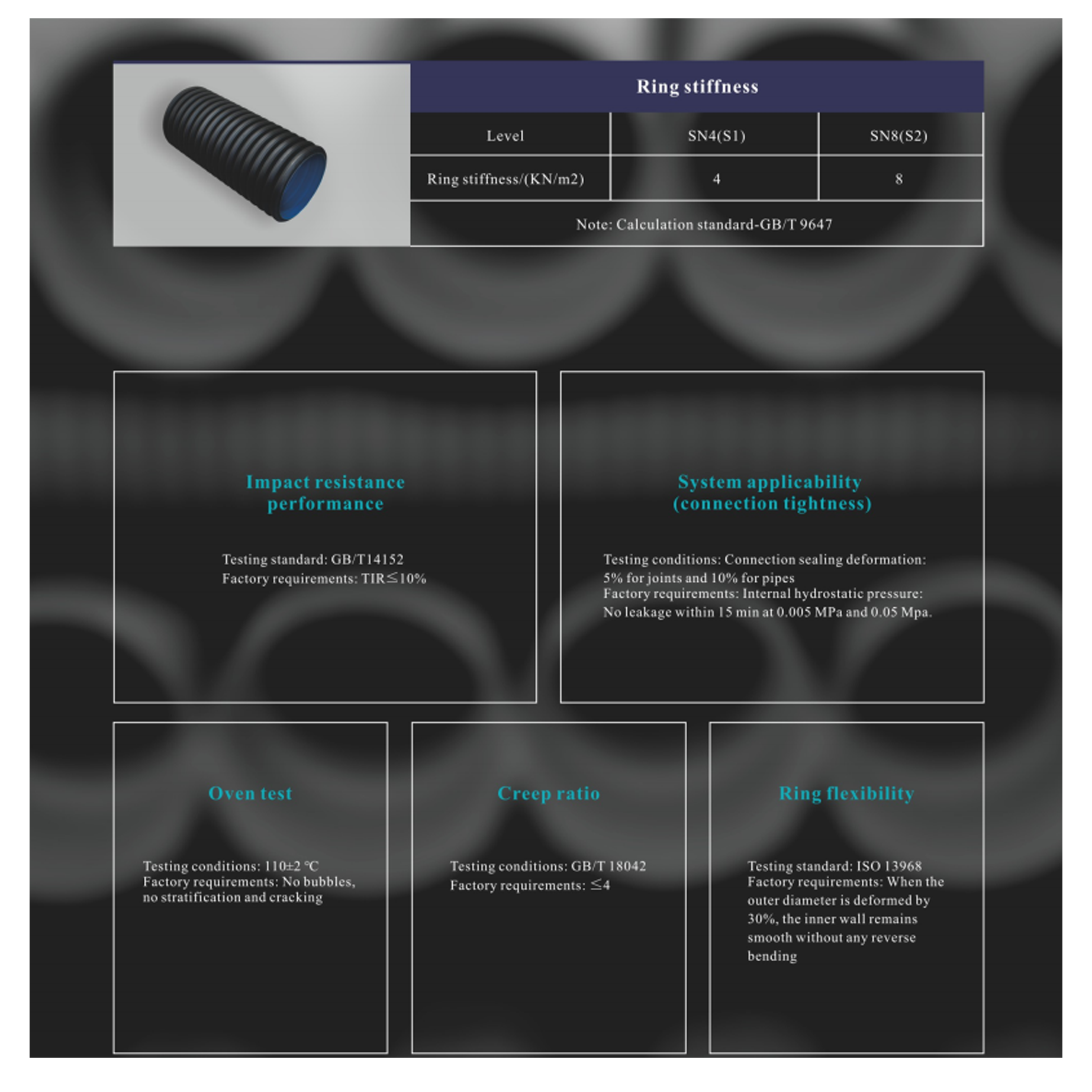

Ring Stiffness Class | Common classes are SN4 and SN8 (corresponding to the old S1 and S2 grades). High ring stiffness models effectively resist soil loads. |

Operating Temperature Range | -40°C to 60°C. Some data indicates a low embrittlement temperature down to -70°C, demonstrating excellent cold resistance. |

Primary Raw Material | High-Density Polyethylene (HDPE) resin, with necessary additives. |

Single Pipe Length | Standard length for pipes with bell-and-spigot ends is 6 meters |

Color | Common colors are black exterior with blue interior, or all black. Other colors like orange are also available. |

Service Life | Can exceed 50 years under buried conditions without direct exposure to sunlight/UV radiation. |

3.Connection Methods

The HDPE double-wall corrugated pipe primarily utilizes the bell-and-spigot joint method, coupled with an elastic sealing ring. This flexible joint design ensures excellent sealing performance at the connections, effectively resisting leakage caused by differential settlement of the foundation.

4.Key Advantages & Selling Points

- High Pressure Resistance:The outer wall’s annular corrugated structure significantly enhances the pipe’s ring stiffness, providing superior resistance to soil loads compared to many other pipe materials.

- Cost-Effectiveness:Under equivalent load conditions, it requires a thinner pipe wall, saving approximately half the raw material compared to solid-wall pipes of the same specification, resulting in lower overall project costs.

- Easy Installation:The pipes are lightweight (weight per meter is only 1/8 of that of traditional concrete pipes), making handling and connection easier. This significantly improves construction efficiency and shortens project timelines.

- Excellent Hydraulic Performance:The smooth inner wall creates low friction resistance, allowing for greater flow capacity or higher flow velocity within pipes of the same diameter.

- Chemical Corrosion Resistance:HDPE molecules are non-polar, granting exceptional chemical stability and resistance to corrosion from most chemical media.

- Flexibility & Impact Resistance:The pipes offer good flexibility and outstanding low-temperature impact resistance (embrittlement temperature as low as -70°C), allowing them to adapt to a certain degree of uneven settlement.

- Durability & Abrasion Resistance:The abrasion resistance is several times that of steel pipes, ensuring a long service life in buried applications.

- Environmentally Friendly & Safe:The material is non-toxic and pollution-free, classifying it as an eco-friendly pipe product.

5.Product Applications

- Municipal Engineering:Urban underground drainage and sewage pipeline networks.

- Construction Engineering:Building rainwater pipes, underground drainage pipes, sewage pipes, ventilation ducts, etc.

- Industrial Applications:Effluent and drainage pipes for chemical plants, hospitals, environmental protection facilities and other industries.

- Transportation & Mining:Seepage and drainage pipes for railways and highways; mine ventilation, air supply, and drainage.

- Agriculture & Water Conservancy:Irrigation and drainage pipes for farmland, orchards, tea plantations, and forest belts.

- Cable Protection:Protective conduits for communication cables and optical fiber cables.

6.Testing & Certifications

- Testing Standards:Primarily complies with national standards such as GB/T 19472.1-2019.

- Test Items:Include visual inspection, dimensions (average outer diameter, inner diameter, wall thickness), ring stiffness, impact resistance, ring flexibility, and oven test.

- Testing Agencies:Authorized third-party testing institutions with qualifications like CMA and CNAS (e.g., Zhonggang Guojian) can be commissioned to conduct testing and issue nationally recognized inspection reports.

- Corporate Qualifications:Manufacturing enterprises are typically ISO9001 Quality Management System certified. Some premium brands have also received honors such as “National Trustworthy Quality Product.”

7.Manufacturing Process Flow

- Raw Material Preparation:High-density polyethylene (HDPE) resin is used as the primary raw material.

- Co-Extrusion Molding:Typically, two single-screw extruders are employed simultaneously to plasticize the material and jointly form the inner and outer walls of the pipe.

- Temperature Control:The barrel temperature of the extruders is generally controlled between 170°C and 210°C, while the die head temperature is maintained between 200°C and 210°C.

- Corrugation Forming:The “external vacuum suction, internal air pressure” calibration technique is applied. The outer wall corrugations are formed via vacuum adsorption (vacuum degree: -0.08 to -0.07 MPa), while the smooth inner wall is shaped by compressed air blowing (pressure: 0.03 to 0.06 MPa).

- Cooling and Cutting:The formed pipe is cooled and then cut to specific lengths (e.g., 6 meters).

8. Packaging and Delivery

- Packaging Method:Pipes can be protectively packaged using materials such as plastic film. To optimize transportation space and cost, smaller diameter pipes can be nested inside larger ones.

- Standard Length:The standard pipe length is typically 6 meters per piece.

- Delivery Capability:Large-scale manufacturers possess robust supply capabilities. For example, some have an annual production capacity exceeding 180,000 metric tons, ensuring timely delivery for major projects.

9. Sales Service

- Full-Process Service:We offer comprehensive support throughout the pre-sale, sale, and post-sale stages. This includes construction drawing optimization, product selection guidance, technical training, installation instruction, and quality inspection assistance.

- Rapid Response Mechanism:We commit to a quick technical support response for any quality issues arising during the warranty period, promising a 1-hour initial response and on-site arrival within 16 hours.

- Support Channels:Remote support is available via phone, WeChat, or video call, supplemented by on-site assistance when necessary.

10. Corporate Strengths

- Scale & Production Capacity:We possess a large-scale production complex equipped with advanced machinery, featuring substantial annual production capacity to meet domestic and international market demands.

- R&D Capabilities:We place strong emphasis on technological research and development, collaborating with universities and research institutions to maintain an ongoing capability for new product innovation.

- Quality Certifications:Our operations are certified under international quality management systems such as ISO9001, and our products have received multiple accolades.

- Project Portfolio:Our products are widely used in national key projects and have been exported to numerous countries, earning a strong market reputation.

Zhongcai(Sancai) Pipe has 20 years of industry experience and serves over 500 customers worldwide. Its advantages include:

- Advanced production capacity: Automated production line with an annual output of over 100000 tons, meeting large-scale demand. R&D Strength: Collaborate with universities to continuously innovate products, such as anti-static PE pipes. Customer case: Successfully participated in the Asian municipal water supply project, with a customer satisfaction rate of 98%. Environmental Commitment: Use recyclable materials, reduce carbon footprint, and support green buildings.

- Strict quality control: Establish a sound quality management system, implement full process quality monitoring from raw material procurement to product delivery, and rigorously inspect every link to ensure reliable product quality.

- Rich industry experience: With years of deep cultivation in the pipe and fittings industry, we have accumulated rich project experience and successfully served numerous large-scale municipal, construction, industrial and other projects, winning widespread recognition and praise from customers.